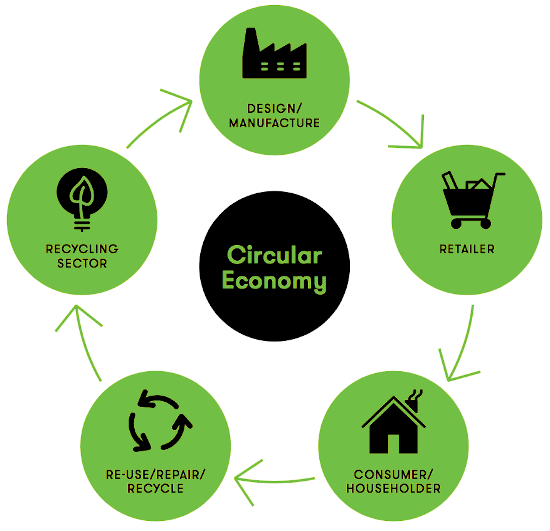

The Circular Economy

Specifically, this includes:

Reducing Resource Consumption through Sharing

As shared, open, peer-learning spaces, they enable use of shared access to equipment, along with the potential for expanding this more widely into the community via initiatives such as tool/equipment libraries.

Repair and Reuse

These spaces also provide opportunities for fix-it clinics/repair cafes and other initiatives that promote the circular and collaborative economies — reusing, repairing and fixing things, and transmitting the knowledge of how to do so.

Avoiding Consumption

Digital fabrication techniques - which are often a key element of these spaces - enable productive activity with more precision in the use of materials, creating less waste that needs to be salvaged in the first place. The ability to design to order, customise, and produce in small batches also avoids the wasteful over-production aspects of existing manufacturing.

Recovery and Recycling

At the other end of the materials life cycle, digital fabrication techniques in workshops

offer new opportunities such as RecycleBots, FilaBots and

Precious Plastic

(itself an open source machine that can be fabricated in a makerspace) devices for converting

3D printer and other plastic waste into new filaments for reuse of plastics as 3D printer ‘ink’.

In their operations, these workshops can also be exemplars of source-separated waste and recycling systems and resource

management focused waste contracts, which reward service providers for how much material they recycle, rather than just a

fee for emptying bins.

(source: Green Industries SA)

They offer people a means of actively participating in provisioning for themselves, rather than being passive recipients of an often impenetrable supply chain and associated invisible environmental and social impacts scattered across the globe. They offer potential to challenge the primacy of consumption and culture of disposability, and they invite people to remember and (re)discover they are citizens, not just consumers. These wider cultural shifts are critical in order to meet the objective of creating a circular economy.

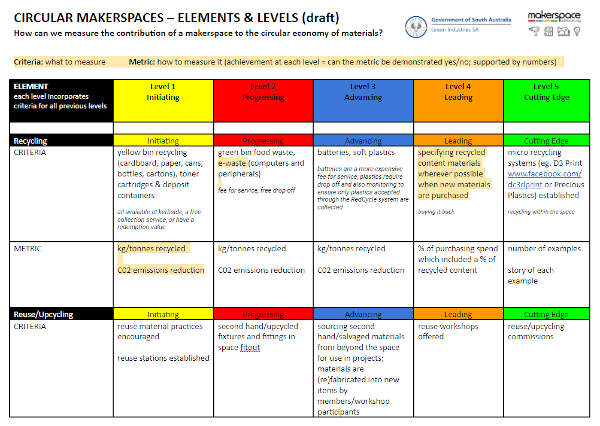

Measuring the Impact of the Circular Economy at Makerspace Adelaide

Waste educators, designers, data geeks, statisticians, hackers and lateral thinkers were invited to contribute their ideas and insights to an important challenge:

How can the contribution of a makerspace to the circular economy be measured?

The aim of the workshop was to determine how to measure and communicate the value of 'circular' practices in a makerspace, and their contribution to circular economy objectives.

This workshop was a hands-on session where participants looked at the circularity of products designed and used in the Makerspace in a ‘product teardown’. Four workstations were set up for textiles, electronics, plastics and wood, reflecting materials used and activities undertaken at the makerspace. Participants were split into teams of 4-5 people and assigned a station.

At the station, they worked as a team through two activities – firstly, investigating the circularity of product design, including material use/origin, ease of disassembly, repairability and recyclability. They were led through a series of questions to help them assess the products, and physically measure and record the findings. Participants then also considered how the products might be redesigned to improve circularity, and how this approach could be encouraged at the makerspace.

Rawtec have complied the workshop findings into this report:

Download Rawtec Workshop Summary Report (PDF)

Circular Economy Workshop - Open Source Materials

If your Makerspace or Fab Lab would like to run this workshop, you can use our materials and adapt them to your own local needs (acknowledgement of the source would be appreciated):- The workshop structure Running Sheet

- The Prompt Cards used at the teardown stations:

- The Data Collection Sheet used to record responses and gather information at each station

- A draft Circular Makerspaces Metrics Framework is available to use or adapt for your local circumstances and/or to make contributions or suggestions to

Acknowledgements

This workshop was designed and delivered by SA Makers, Green Industries SA and Rawtec.Workshop designers: David Riley, Sharon Ede, Kat Heinrich, Oliver Lovat & Kristian Le Gallou

Workshop presenters: Ian Overton, Sharon Ede, David Riley & Kat Heinrich

Facilitators: Kat Heinrich, Sharon Ede, Oliver Lovat, Adara Wright, Bojana Stefanovska, Kristian Le Gallou

Materials experts: Matthew Bagnara, William Chappel, Miheer Fyzee, Len Riley & David Riley

Videographer: Miriam Yip of Environment and Science Media

Thank you to all of the participants, including representatives from Adelaide’s universities, local and international businesses, the charitable recycling sector, local and State government policy makers and program managers, waste educators, repair cafes and the social enterprise sector.